Pouch Bag Labeling Machine

Leading bag labeling solutions designed to fulfill the production requirements of various industries. Request a quote today!

LMS offers 3 types of bag labeling machine

These bag labeling equipment manufactured by LMS are mainly used to stick the adhesive label rightly on the flat surfaces of paged flat bags, pouches, paper, cards, and envelopes.

Check these 3 types of labler applicator machines for bags and pouches:

Bag top labeling machine

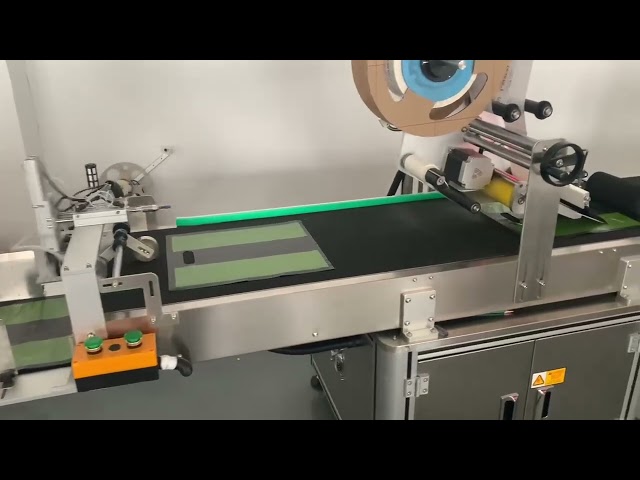

This BGJ-P220 automatic labeling machine is designed for labeling the top of filled bags and empty bags with flat surface. It is equipped with a high-precision labeling function. The labeling accuracy can reach ±1mm, to ensure the accurate positioning of labels on a variety of products. The machine is made of stainless steel and high-quality aluminum alloy, with a sturdy structure and easy operation and maintenance, which is especially suitable for applications in narrow spaces.

The BGJ-P220 is equipped with an advanced electrical control system, including Mitsubishi PLC, Velcom touch screen, and a banner sensor to ensure stable operation and smooth labeling process. In addition, it supports a wide range of label sizes and speed adjustments for a wide range of applications to meet the needs of different industries.

The labeling machine also features automatic fault alarms and production counting, further improving production efficiency and safety. If more efficient automated production is required, the optional AXF26 automatic feeder can be used to create a fully automatic feeding and labeling process.

What are its features?

What other features can it be upgraded with?

Plastic bag labeling machine

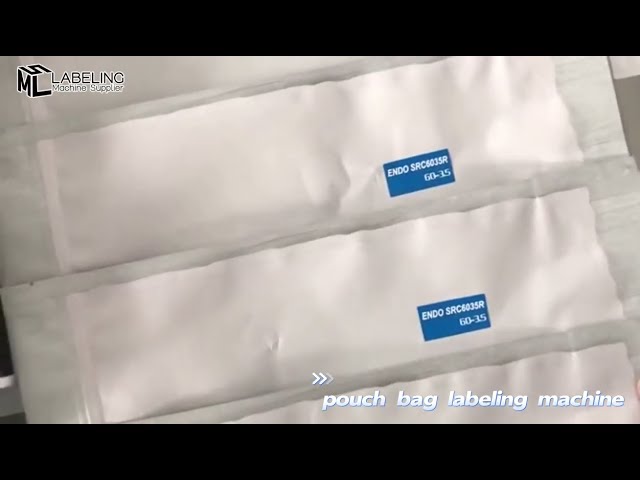

Tailored for flat pouch products, the friction type pagination labeling machine delivers efficient and accurate labeling. Built with stainless steel and premium aluminum alloy, it offers a sturdy construction and simple operation, handling various pouch sizes. Achieving a labeling precision of ±1mm, it guarantees precise label placement, significantly improving product aesthetics.

Featuring an advanced electrical control system, friction-type feeding mechanism, and an intuitive touch screen interface, the devices allows for easy adjustments and monitoring of the labeling process. Versatile in label size and speed adjustments, it accommodates diverse industry requirements. Its compact design ensures efficient utilization of space.

Moreover, the machine incorporates automatic material separation and collection, ensuring a seamless production flow. For enhanced automation, an optional automatic feeder is available.

What are its features?

What other features can it be upgraded with?

Automatic soft bag labeling machine

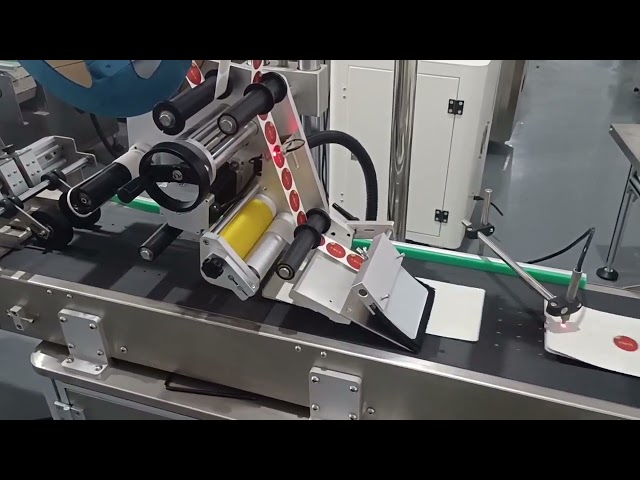

This automatic paging labeling machine, designed to significantly enhance labeling efficiency and accuracy, the pneumatic split bag labeling machine is specially engineered for various soft plastic bag labeling applications, and for big bag, food bag paging. By automating bag feeding and label detection, it effectively eliminates label misalignment, bubbles, wrinkles, and inconsistent positioning commonly associated with manual labeling, ensuring precise label placement every time.

Constructed with stainless steel and high-quality aluminum alloy, the machine boasts a robust and durable design while maintaining ease of operation, making it ideal for high-efficiency production environments. It accommodates a wide range of bag sizes and can be customized to meet specific customer requirements. With a labeling accuracy of ±1mm and the ability to fine-tune to precise technical parameters, it guarantees exceptional precision.

The BGJ-F300 features a compact design, minimizing its footprint and allowing for flexible placement within production facilities. Its integrated conveyor system ensures stable product transport during the labeling process, further enhancing accuracy and production efficiency. Additionally, the machine is equipped with a positioning device, fault alarm system, production counter, and an optional printing function to meet diverse production needs.

For higher levels of automation, the machine can be integrated with a suction feeding device and conveyor system to form a fully automated labeling process.

What are its features?

What other features can it be upgraded with?

Our bag labeling machines are suitable for

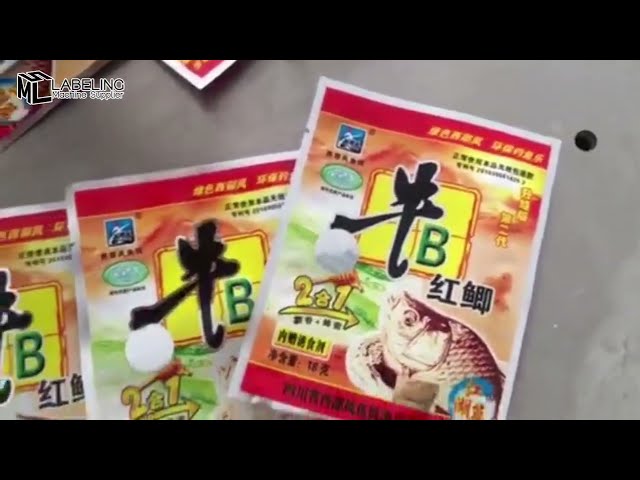

LMS’s machines are suitable for labeling bags made of plastic, paper, and other materials, which are widely used in the food, packaging, pharmaceutical, and other industries, the following are examples of our applications:

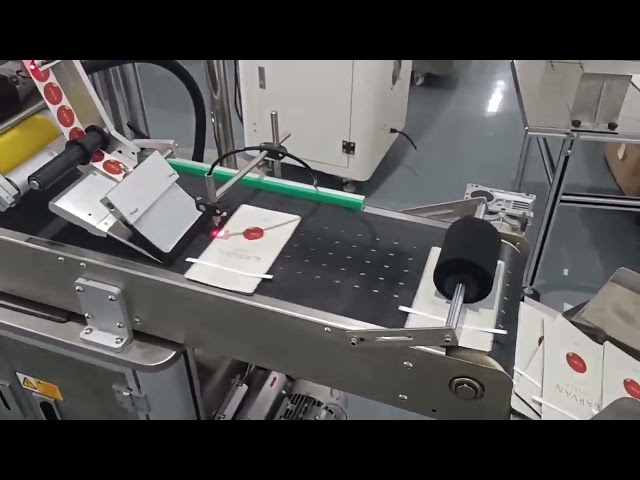

Bag labeling test video in the factory

We recognize the importance of reliable performance in your operations. Therefore, each bag labeling machine we offer undergoes a comprehensive Factory Acceptance Test (FAT) to ensure it meets your precise requirements. This test rigorously examines the machine to confirm its correct functionality.

Here are some videos demonstrating our bag labeling process:

Plactic labeling machine video

Mylar bag labeling machine video

Pouch bag labeling machine video

Automatic bag labeling machine video

Coffee bag labeling machine video

Coffee bag labeling machine video

For bag labeling, we have abundant cases:

After watching our machine test videos, you may be skeptical about the labeling capabilities of LMS equipment. We have a wealth of bag labeling case studies to allay your fears:

big size grain bags

paper bread bag

paper steak bag

plastic bag

plastic food bag

Why is LMS the first choice for bag labeling?

During the bag labeling process, you may encounter challenges such as diverse bag materials and surface treatments, irregular bag shapes and sizes, and complex label content with high printing requirements. LMS labeling systems can alleviate all your concerns.

Our equipment excels in bag labeling and employs cutting-edge technology specifically designed to meet the unique packaging needs of bags. Our machines can adapt to various shapes and flat bags, achieving a labeling accuracy rate of up to 99.9% while minimizing product and label damage.

Our equipment is robust, durable, and has low maintenance costs, ensuring long-term reliability. From initial consultation to comprehensive after-sales support, we are committed to optimizing your operations.

If our standard machines do not fully meet your requirements, our customization services can provide tailored solutions. From careful planning and precision manufacturing to rigorous testing and seamless installation, we offer end-to-end support.

Offer these information to customize your bag labeling machine: such as bag size, label size, label position on bag, speed requirement (how much labeling needs to be done per minute or per hour), and other specific needs.

FAQs

- What types of bags can your labeling machines handle?

Our bag labeling machines are designed to handle a wide variety of bags, including flat sealed-edge bags, paper bags, flat bags, tinfoil bags, sealed bags with outlets, sealed bags, and plastic square bags. Whether you need to label small pouches, large plastic bags, or anything in between, our machines can be customized to meet your specific requirements.

- What kind of labels can your machines apply?

Self-adhesive labels or self-adhesive paper labels.

- What industries are your bag labeling machines suitable for?

Our pouch labeling machines are versatile and can be used across various industries, including food and beverage, pharmaceuticals, cosmetics, and more. Whether you’re labeling mylar bags, coffee bags, or any other type of product packaging, our machines are designed to meet the specific needs of your industry.

- What’s the difference between pneumatic and friction bag feeding for labeling?

Pneumatic bag feeding uses air pressure to separate bags, while friction feeding relies on mechanical friction. Pneumatic systems are often faster but can be more complex and costly.

- What information should a bag label include?

A bag label typically includes: brand name, product model, material, size, origin, care instructions, and any mandatory legal information as required by regulations in the specific region.

- How quickly can a bag labeling machine return to production in the event of a malfunction?

Most models are designed with a quick troubleshooting system and easy-to-replace modular components for a swift return to production. Our machines also come with fault counseling and repair services, so you don’t have to worry.

- Do you offer training for operating and maintaining the machine?

Indeed, we offer comprehensive online training sessions at no cost, designed to equip you with all the necessary skills and knowledge for the effective operation and upkeep of your machine.

- What does the warranty for the machines cover?

Our machines come with a standard one-year warranty, with the option to extend it for longer coverage and added security.